旋转供料器是一种散装物料输送的主要设备,也是气力输送中不可缺少的一部分。可靠性强,并且实惠一般用于粮食加工,化工原料 塑料冶金,能源矿业,建材水泥,码头等行业。旋转供料器一般分为标准旋转供料器,耐磨旋转供料器,变频旋转供料器,侧置旋转供料器等10个型号1400多种类型。

The rotary feeder is a main equipment for conveying bulk materials and an indispensable part of pneumatic conveying. Strong reliability and affordable price are generally used in grain processing, chemical raw materials, plastic metallurgy, energy mining, building materials, cement, wharf and other industries. The rotary feeder is generally divided into 10 models and more than 1400 types, including standard rotary feeder, wear-resistant rotary feeder, variable frequency rotary feeder and side-mounted rotary feeder.

旋转供料器作为气力输送设备一般搭配加速室和抽气室一起使用。

As a pneumatic conveying equipment, the rotary feeder is generally used together with the accelerating chamber and the pumping chamber.

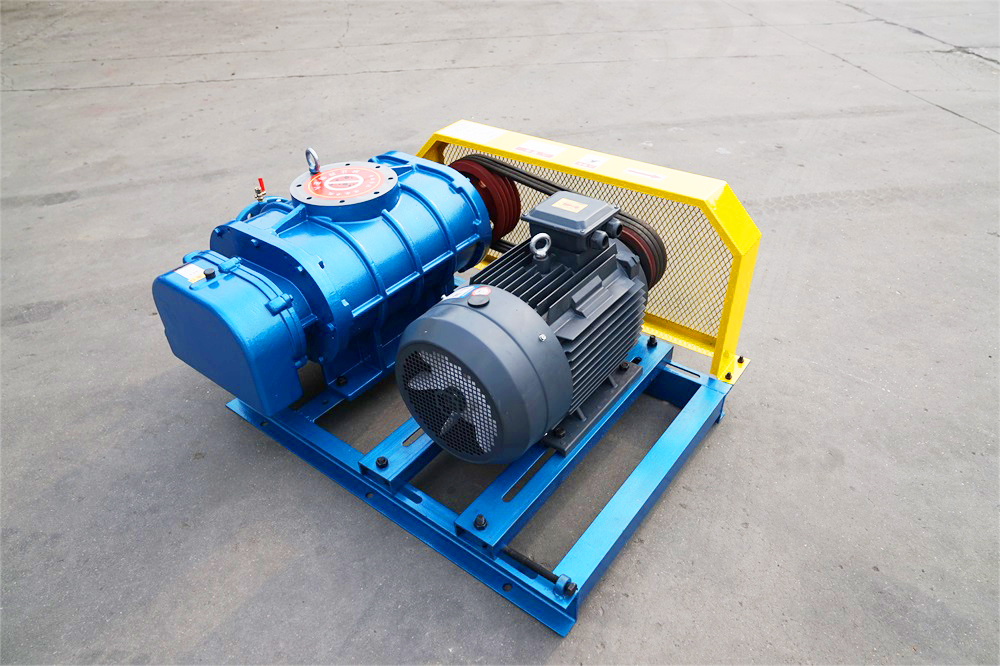

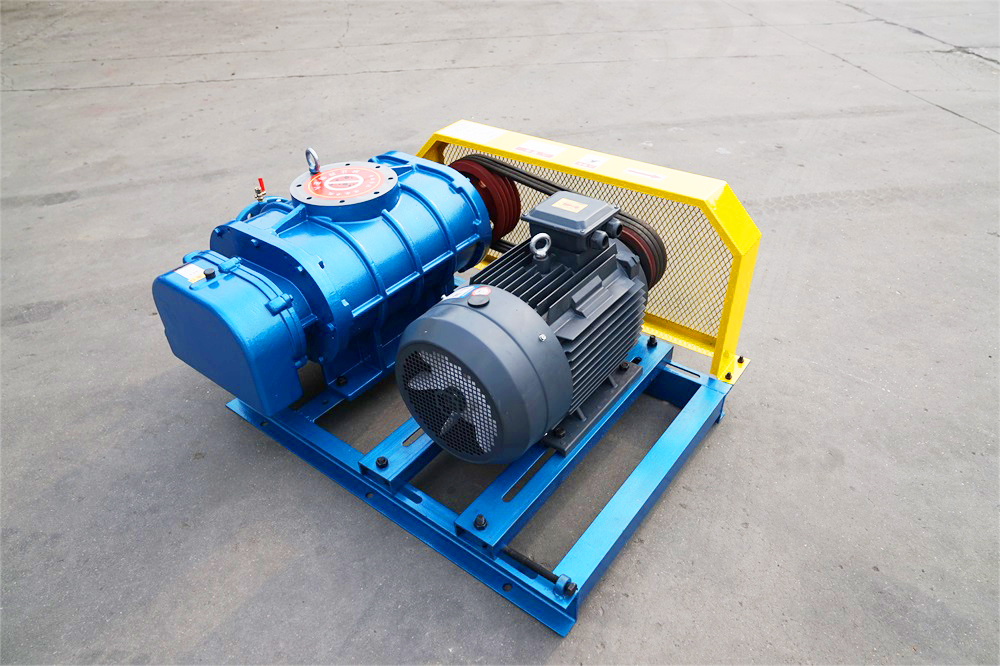

产品介绍:

Product introduction:

耐磨型旋转阀主要针对耐磨性强的粉颗粒料输送,其显著的区别是,阀体内壁与物料接触部分喷涂了耐磨材料.

Wear-resistant rotary valve is mainly used for conveying powder and particle materials with strong wear resistance. Its notable difference is that the contact part between the inner wall of the valve body and the material is sprayed with wear-resistant materials

工作原理:

working principle:

旋转供料器又称旋转阀、星型下料器、锁气器、关风器,通常的旋转供料器结构是带有数个叶片的转子在圆筒形的机壳内旋转,从上部料斗落入的物料,充塞在叶片间的空格内,随叶片的旋转到下部而卸出,机体侧面设有均压吸气口,可将叶轮回转带来的高压气体从此口吸走, 减少气体顶料现象,有利于物料的顺利下落 对于压送式、吸送式气力输送系统,旅转供料器是主要的组成部件之一,它可以均匀而连续的向输料管内供料,而在系统的分离、收尘部,它又具备卸料器的功能。

Rotary feeder is also known as rotary valve, star-shaped feeder, air lock, and air shutoff. The normal structure of rotary feeder is that the rotor with several blades rotates in the cylindrical casing. The material falling from the upper hopper is filled in the space between the blades and discharged as the blades rotate to the lower part. The side of the body is equipped with an equalizing suction port, which can suck the high-pressure gas brought by the rotation of the impeller away from the port and reduce the phenomenon of gas jacking, It is conducive to the smooth fall of materials. For the pressure and suction pneumatic conveying system, the traveling feeder is one of the main components. It can supply materials uniformly and continuously into the conveying pipe. In the separation and dust collection part of the system, it also has the function of a discharger.

特点:

characteristic:

耐磨型旋转阀壳体和主要零件均采用紧密铸造,构造坚固,高强度不易变形,外形美观;

The wear-resistant rotary valve shell and main parts are made of tight casting, with solid structure, high strength and not easy to deform, and beautiful appearance;

壳体和叶轮经过特殊结构的设计和处理,能输送高温、高压、高硬度、高粘性、易产生静电、超细等特殊物料;

The shell and impeller are designed and processed with special structure, which can transport special materials such as high temperature, high pressure, high hardness, high viscosity, easy to generate static electricity, ultra-fine, etc;

壳体进出口截面特殊,有效防止颗粒物料的挤压卡料和剪切破碎

The inlet and outlet sections of the shell are special, which can effectively prevent the extrusion, clamping and shearing of granular materials

壳体内设计有平衡压力用的排气通道和排气管接口,能提高工作效率,不会积存物料

The shell is designed with exhaust channel and exhaust pipe interface for balancing pressure, which can improve the working efficiency and will not accumulate materials

什么是旋转供料器?旋转供料器又称旋转阀、星型下料器、锁气器、关风器,通常的旋转供料器结构是带有数个叶片的转子在圆筒形的机壳内旋转,从上部料斗落入的物料,充塞在叶片间的空格内,随叶片的旋转到下部而卸出,

What is the rotary feeder? Rotary feeder is also known as rotary valve, star-shaped feeder, air lock, and air shutoff. The normal structure of rotary feeder is that the rotor with several blades rotates in the cylindrical casing. The material falling from the upper hopper is filled in the space between the blades and discharged as the blades rotate to the lower part,

The above highlights are from Guangdong rotary feeder. For more highlights, please click to enter our website: http://www.sddyfd.com We will continue to share with you in the future!