气力输送系统利用气流沿管路输送散粒物料的装置。有吸送式、压送式和混合式三种。其工作原理是利用气流的动能使散粒物料呈悬浮状态随气流沿管道输送。广泛应用于食品、化工、医药、橡塑等行业。

Pneumatic conveying system is a device that uses air flow to transport bulk materials along the pipeline. There are three types: suction type, pressure type and mixed type. Its working principle is to use the kinetic energy of the air flow to make the bulk materials suspended and transported along the pipeline with the air flow. It is widely used in food, chemical, pharmaceutical, rubber and plastic industries.

气力输送方式

Pneumatic conveying mode

1、按照每单位体积的气体载体中所携带的粉体的质量多少可分为:稀相气力输送和浓相气力输送,而浓相气力输送又分为浓相动压气力输送和浓相静压栓流气力输送。

1. According to the mass of powder carried in the gas carrier per unit volume, it can be divided into dilute phase pneumatic conveying and dense phase pneumatic conveying, while the dense phase pneumatic conveying can be divided into dense phase dynamic pressure pneumatic conveying and dense phase static pressure plug flow pneumatic conveying.

2、按照输送方式气力输送粉状物料的系统形式大致分为正压气力输送、负压气力输送。

2. According to the conveying mode, the system form of pneumatic conveying of powdery materials can be roughly divided into positive pressure pneumatic conveying and negative pressure pneumatic conveying.

气力输送方式详解

Detailed explanation of pneumatic conveying mode

①吸送式。抽风机启动后,整个系统呈一定的真空度,在压差作用下空气流使物料进入吸嘴,并沿输料管送卸料处的分离器内,物料从空气流中分离后由分离器底卸出,气流经除尘器净化后再经消声器排入大气。优点是供料简单,能从数处同时吸取物料。但输送距离短,生产率低。密封性要求高。

① Suction type. After the exhaust fan is started, the whole system assumes a certain degree of vacuum. Under the effect of pressure difference, the air flow makes the material enter the suction nozzle, and is sent to the separator at the discharge place along the material delivery pipe. The material is separated from the air flow and discharged from the bottom of the separator. The air flow is purified by the dust collector and then discharged into the atmosphere through the muffler. The advantage is that the material supply is simple, and the material can be absorbed from several places at the same time. However, the conveying distance is short and the productivity is low. High sealing requirements.

吸送式气力输送系统

Suction pneumatic conveying system

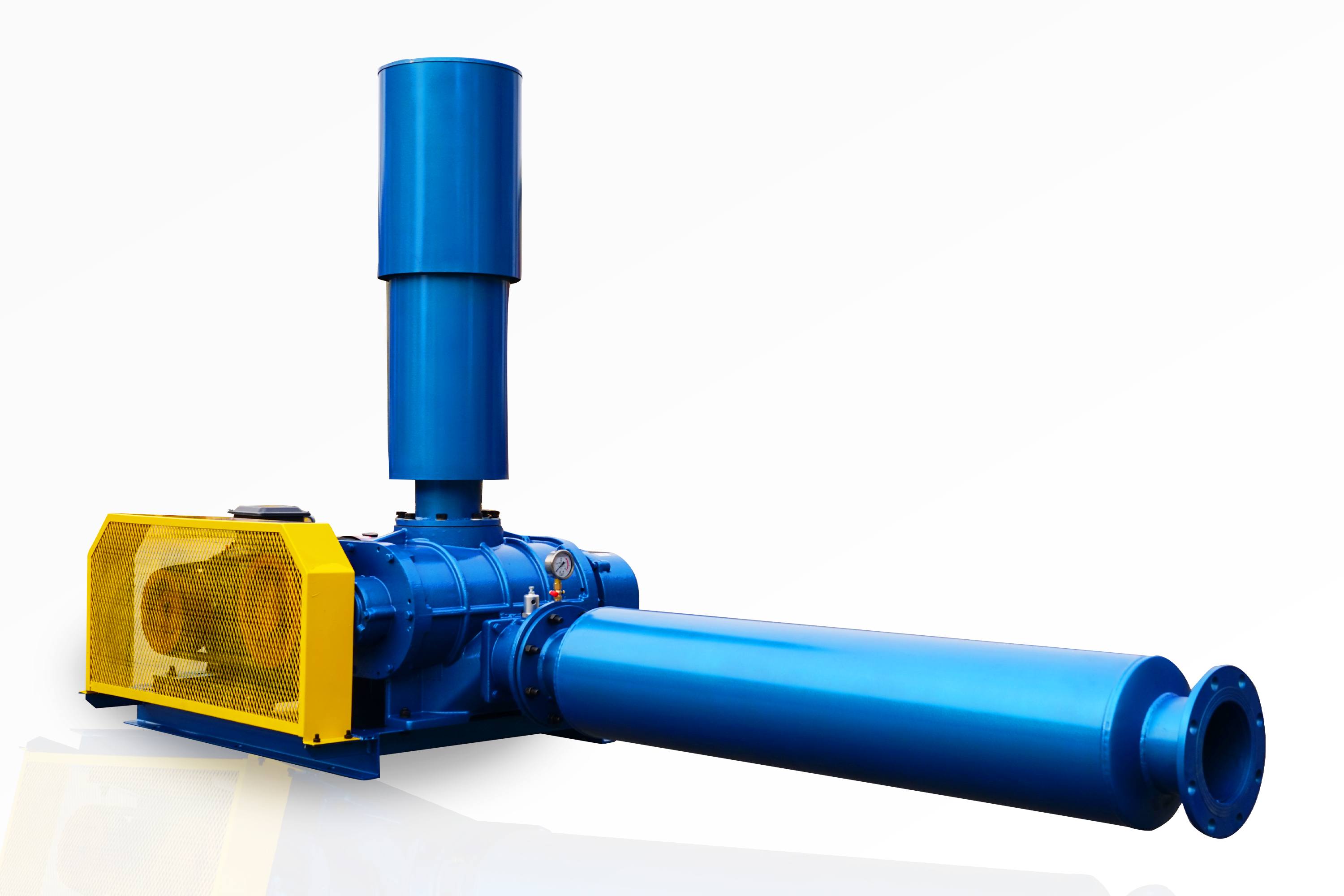

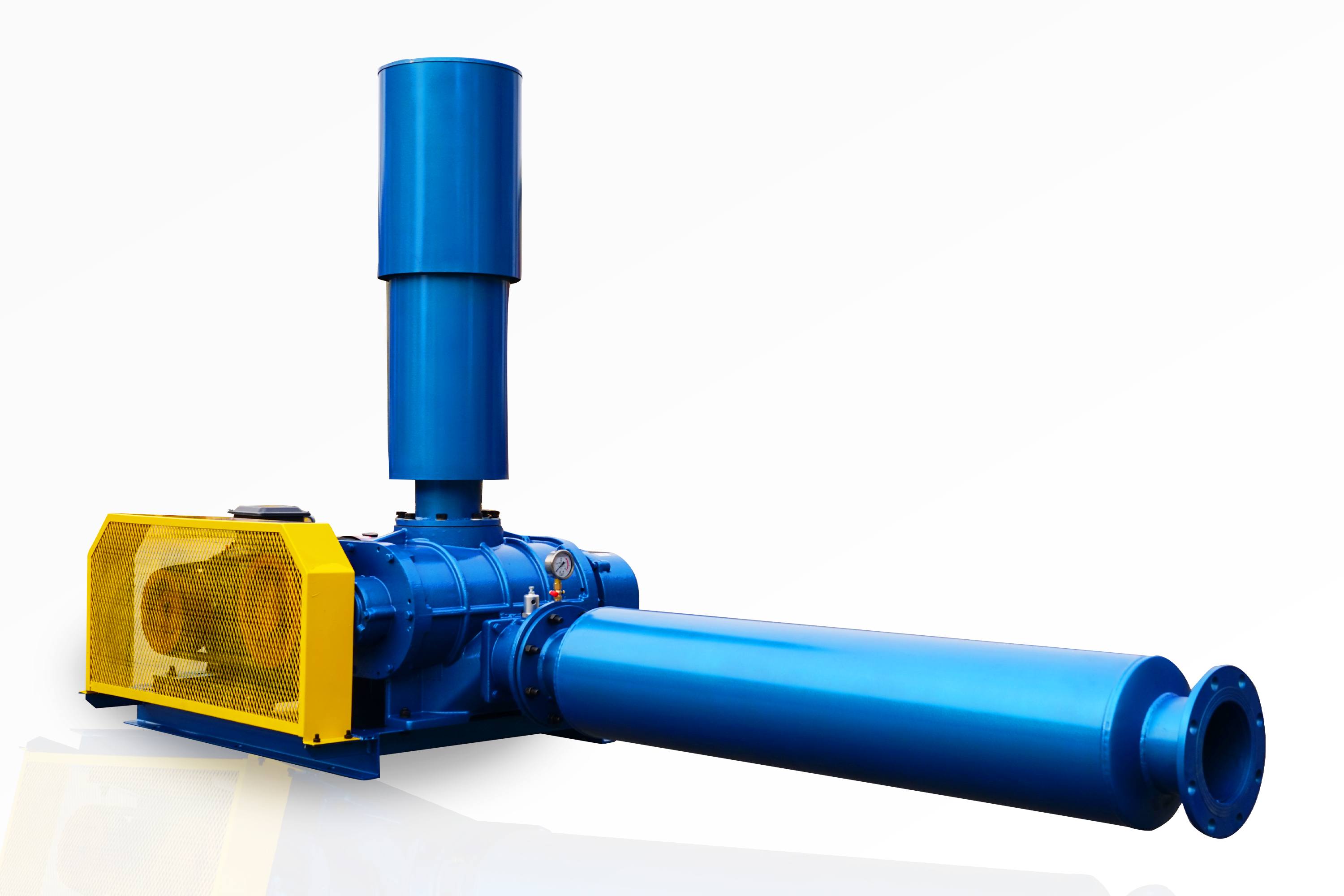

②压送式。罗茨鼓风机将空气压入输送管,物料从供料器供入,空气和物料的混合物沿输料管被压送卸料处,物料经分离器后卸出,空气经除尘器净化后排入大气。特点与吸送式相反,可同时将物料输送到几处,输送距离较长,生产率较高,但结构复杂。

② Press type. Roots blower will press air into the conveying pipe, and materials will be supplied from the feeder. The mixture of air and materials will be pressed to the discharge place along the conveying pipe, and the materials will be discharged after the separator, and the air will be discharged into the atmosphere after being purified by the dust collector. Contrary to the suction type, it can transport materials to several places at the same time, with a long conveying distance, high productivity, but complex structure.

压送式气力输送系统

Pressure pneumatic conveying system

③混合式。为上述两种形式的组合。

③ Hybrid. Is a combination of the above two forms.

吸送式、压送式相结合气力输送系统

Combined pneumatic conveying system of suction and pressure

气力输送系统与机械式连续输送装置相比,其特点是:物料在输送过程中完全密闭,受气候和环境的影响小,工人工作条件好,物料不致受潮、污损或混入杂质,设备简单,结构紧凑,布置灵活,占地较小,设备费用低,可同时进行某些工艺(如粉碎、烘干、分级)作业,易于集中控制,可实现自动化,提高输送能力。除易碎、粘附性强、磨琢性大、有腐蚀性和易起化学变化的物料需特殊处理外,一般松散物料均可输送。

Compared with the mechanical continuous conveying device, the pneumatic conveying system has the following characteristics: materials are completely closed during the conveying process, less affected by the climate and environment, good working conditions for workers, materials will not be affected by moisture, dirt or impurities, simple equipment, compact structure, flexible layout, small floor space, low equipment cost, and can carry out some processes (such as crushing, drying, grading) at the same time, easy to centralized control, and can achieve automation, Improve the conveying capacity. In addition to the materials that are fragile, adhesive, abrasive, corrosive and prone to chemical change, which need special treatment, generally loose materials can be transported.

缺点是能耗较大,对物料的块度、粘性和湿度有一定限制,风机噪声大,输送磨削性物料时,管道易磨损。为克服上述缺点,正在发展一种静压式输送装置。其基本原理是在输送管中形成许多彼此相间的料栓和气栓,用空气压力推送料栓前进以达到输送的目的。

The disadvantage is that the energy consumption is large, and there are certain restrictions on the size, viscosity and humidity of materials. The fan noise is large, and the pipeline is easy to wear when conveying abrasive materials. In order to overcome the above shortcomings, a hydrostatic conveying device is being developed. Its basic principle is to form many material plugs and air plugs in the conveying pipe, and push the material plug forward with air pressure to achieve the purpose of conveying.

此外,还有将气流充入粉状物料中,使物料流动性好而便于输送的空气输送斜槽气力输灰系统装置属于密相中压气力输送,适用于不易破碎颗粒、粉料物料的输送。

In addition, there is also an air conveying chute pneumatic ash conveying system device that fills the air flow into the powder material to make the material flow well and easy to transport. The device belongs to dense phase medium pressure pneumatic conveying, and is applicable to the transportation of non-fragile particles and powder materials.